In the evolving landscape of sustainable food production, Pureture stands out as a biotechnology company revolutionizing the creation of plant-based casein proteins. By leveraging traditional fermentation techniques and innovative processes, Pureture aims to replicate the functional and nutritional properties of dairy casein without relying on animal sources. This article delves into the intricacies of Pureture’s process, its advantages, and the challenges it faces in the market.

Understanding Pureture’s Process

Pureture’s approach centers on a six-step traditional liquid fermentation process to produce plant-based casein protein:

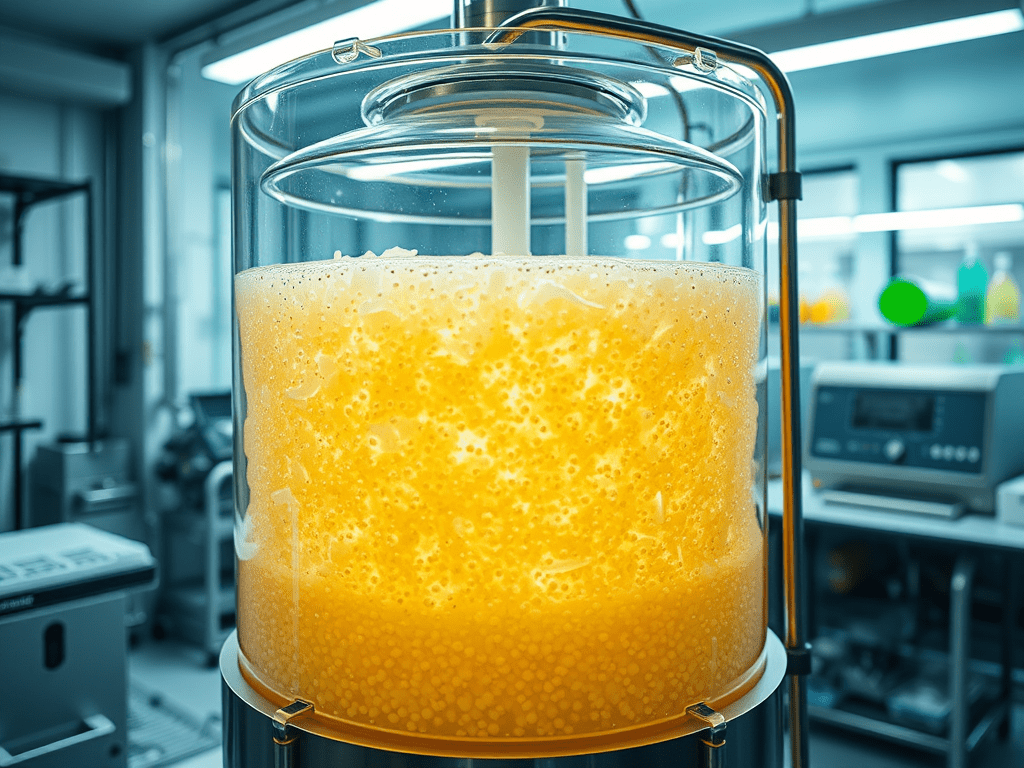

- Yeast Cultivation: The process begins with cultivating a proprietary yeast strain in a 50-liter fermentation tank.

- Enrichment: The yeast undergoes an enrichment phase to enhance protein expression.

- Protein Separation: Proteins are extracted from the yeast biomass.

- Functionality Testing: The emulsification properties of the protein are assessed to ensure they meet desired standards.

- Sterilization: The protein is sterilized to ensure safety and stability.

- Spray Drying: Finally, the protein is converted into a powder form through spray drying, making it suitable for various applications.

This method allows for the production of 200 tons of protein per month, totaling 2,400 tons annually.

Advantages of Pureture’s Approach

1. Efficiency and Cost Reduction

By reducing cultivation time by up to 30%, Pureture’s process enhances production efficiency, leading to significant cost savings. The continuous nature of the process allows the company to offer its plant-based casein at prices 20% to 30% lower than traditional dairy ingredients.

2. Elimination of Additives

Traditional yeast cultivation often requires antifoaming agents due to foam formation. Pureture’s technology virtually eliminates foam, reducing the need for such additives and aligning with the clean-label movement.

3. Functional Integrity

The plant-based casein produced retains essential functional properties like emulsification and thickening, making it suitable for applications in milk, cheese, and protein shakes.

4. Sustainability

Utilizing molasses, a by-product of sugarcane processing, as a nutrient source for yeast cultivation exemplifies Pureture’s commitment to upcycling and reducing environmental impact.

5. Regulatory Advantages

Employing traditional fermentation methods allows Pureture to bypass certain regulatory hurdles associated with genetically modified organisms, facilitating a smoother market entry.

Challenges and Obstacles

1. Scaling Production

While current production capabilities are substantial, scaling up to meet global demand requires significant investment in infrastructure and logistics.

2. Market Acceptance

Educating consumers about the benefits and equivalence of plant-based casein compared to dairy casein is crucial for widespread adoption.

3. Competition

The alternative protein industry is rapidly evolving, with companies like DairyX, New Culture, and Eden Brew developing similar technologies.

4. Regulatory Landscape

Despite advantages, navigating the complex regulatory environments across different countries remains a challenge, especially as the company seeks to expand globally.

Conclusion

Pureture’s innovative approach to producing plant-based casein protein positions it as a leader in the alternative dairy sector. By combining efficiency, sustainability, and functionality, the company addresses key challenges in food production. However, to fully realize its potential, Pureture must navigate scaling, market acceptance, competition, and regulatory complexities. With continued innovation and strategic planning, Pureture is poised to contribute significantly to the future of sustainable and health-conscious food alternatives.

Leave a comment